Why do you need Stiffeners on Flex PCB?Tuesday,Dec 11,2018

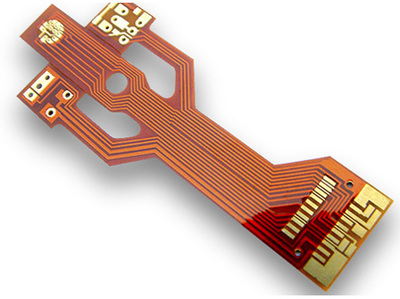

Flex PCBs are thin, light weight and easy bending, this gives much difficulty in the process of component assembly. Stiffeners are used to reinforce those areas where components will be assembled. There are many different material can be used as stiffeners, like polyimide, kapton, FR-4, Aluminium, etc, designer need to select the right material based on their thickness and characteristics.

There are many benefits of using a stiffener 1. Stiffeners are an inexpensive option for rigidizing pin areas, surface mount areas, or hole patterns for component mounting. 2. Stiffeners can be utilized to force a bend line in selected areas. 3. Stiffeners reinforce solder joints and increase abrasion resistance. 4. Circuits may be attached to a stiffener pallet (multiple parts) to provide easier handling for automated pick-and-place and component soldering. Circuits can be held together for processing on the pallet, then singulated (clipped free) after wave soldering and circuit testing. 5. Stiffeners can be marked with component mounting locations for rapid assembly. 6. When using multiple stiffeners, maintaining the same stiffener thickness consistent throughout the entire construction can help lower costs. 7. Stiffeners can also be used to perform specific functions such as heat dissipation and strain relief.

|