One article take you to know AL-based boardFriday,Dec 14,2018

Many customers and electronic designers were asking questions about the aluminum-based board, today our chief technical official Luca Zhang shared the knowledge and experience to you.

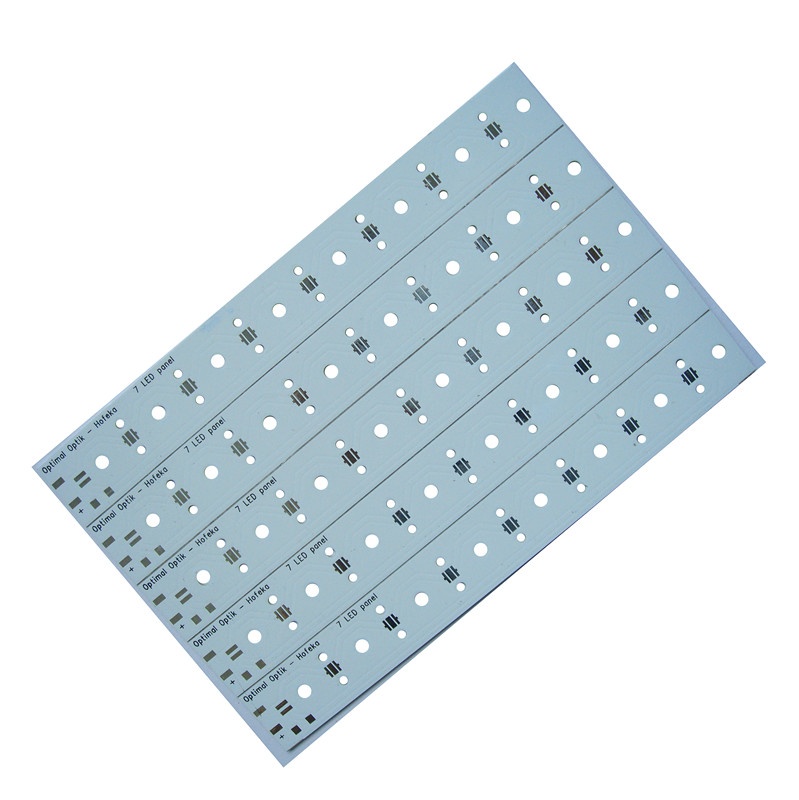

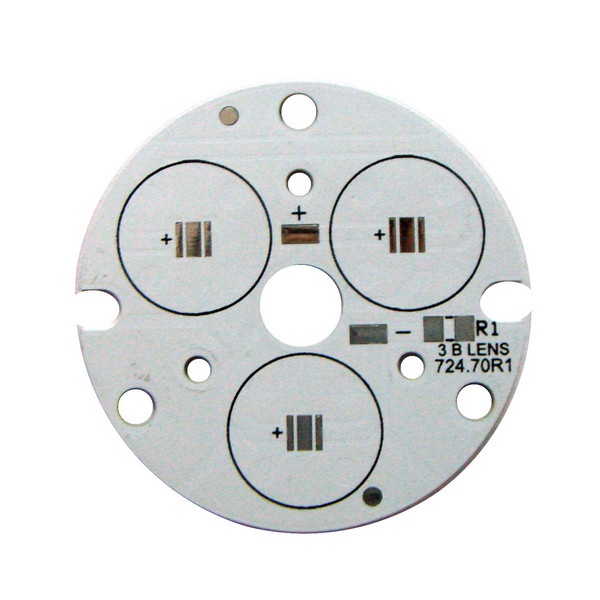

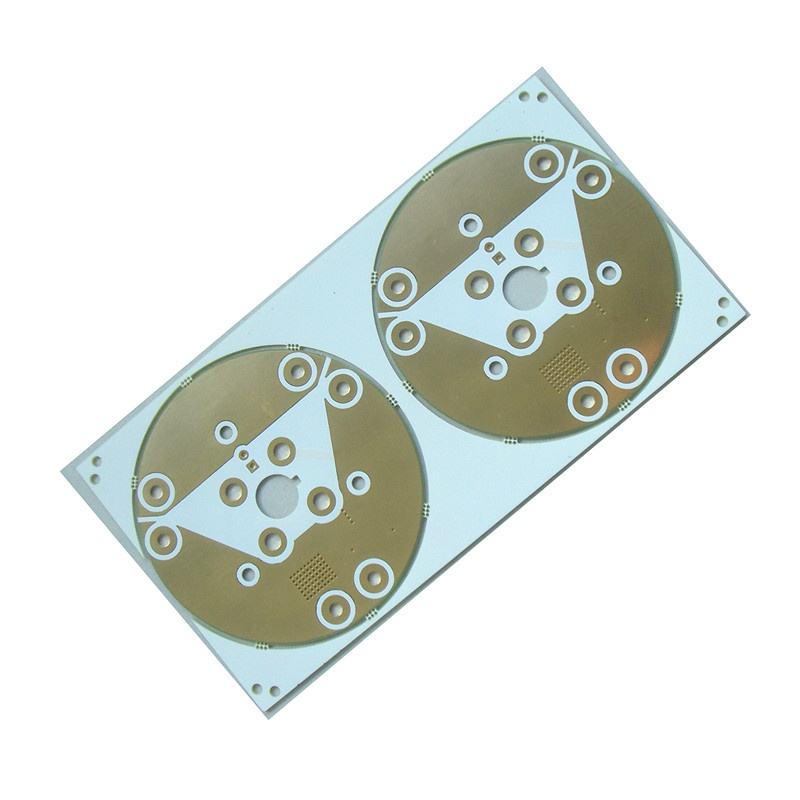

(1) Heat dissipation At present, many double-layer and multi-layer boards have high density, high power and difficult for heat dissipation. Conventional printed board substrates such as FR4 and CEM3 are poor conductors of heat, which are insulated between layers and heat is not emitted. The local heat of electronic equipment is not ruled out, resulting in electronic components invalid, the aluminum substrate can solve this heat dissipation problem. (2) Thermal expansion Thermal expansion and cold contraction are the common nature of substance, and the thermal expansion coefficients for different substances are different. The aluminum-based board can effectively solve the heat dissipation problem, thereby alleviating the thermal expansion and cold contraction of different materials on the printed board, improving the durability and reliability of the whole machine and the electronic equipment. In particular, it solves the problem of thermal expansion and contraction for SMT (Surface Mount Technology). (3) Dimensional stability Aluminum-based boards are obvious much more stable in dimension than insulating materials PCB. When aluminum-based board and aluminum sandwich board are heated from 30 ° C to 140 ~ 150 ° C, the dimensional change is 2.5 ~ 3.0% only. (4) Other reasons Aluminum-based board, which has shielding effect; replaces brittle ceramic substrate; uses surface mounting technology with confidence; reduces the real effective area of printed board; replaces components such as heat sink, improves heat resistance and physical properties of products; reduces production cost and labor. (1) Metal base Aluminum-based substrates, using LF, L4M, and Ly12 aluminum material, require an expansion strength of 30 kgf/mm2 and an elongation of 5%. The US brand Berges aluminum substrate have four types of 1.0, 1.6, 2.0, and 3.2 mm, the aluminum type is 6061T6 or 5052H34. Japan's Matsushita Electric Works, Sumitomo R-0710, R-0771, ALC-1401, ALC-1370 and other models are aluminum-based copper clad laminates, thickness of 1.0 ~ 3.2mm. (2) Insulation layer Insulation, usually 50~200um. If it is too thick, it can act as an insulator to prevent short-circuiting with the metal base, but it will affect the heat dissipation; if it is too thin, it can dissipate heat well, but it is easy to cause the metal core and the component lead to be short-circuited. The insulating layer (or prepreg) is placed on an anodized, insulated, aluminum plate and bonded together by a copper layer on the surface of the laminate.  Aluminum-based copper clad laminates fall into three categories:

The biggest difference between aluminum-based copper clad laminate and conventional FR-4 copper clad laminate is heat dissipation. Compared a 1.5mm thickness FR-4 laminate with a 1.5mm aluminum-based copper clad laminate, the FR-4 laminate has a thermal resistance of 20 to 22 ° C and a thermal resistance of 1.0 to 2.0. °C, but the aluminum-based laminate is much smaller.

As mentioned above, the aluminum substrate has good thermal conductivity, Headpcb followed the market to use aluminum substrate. Therefore, an important criterion for judging the quality of an aluminum substrate is the thermal conductivity of the aluminum substrate, as well as the thermal resistance and the withstand voltage of the aluminum substrate. At present, the general thermal conductivity of aluminum substrates in the market is generally 2.00, and others are 1.0, 1.5, etc., the specific situation depends on the needs of the goods. The specific thermal conductivity of the aluminum substrate can be measured by the instrument. Headpcb’s laboratory have complete sophisticated measure equipment. The thermal conductivity directly affects the price of the aluminum substrate. Generally, the higher the thermal conductivity of the aluminum substrate, the higher the price. However, the quality of the aluminum substrate can not be unilaterally depends on the thermal conductivity only, but also depends on the thermal resistance value and the withstand voltage value. The thermal conductivity of the aluminum substrate is generally fixed and does not change with external factors. The determination of the thermal conductivity is mainly determined by the raw material of the aluminum substrate. If high thermal conductivity materials such as copper and silver are added, the thermal conductivity of the aluminum substrate will definitely be higher. Thermal conductivity is a basic physical quantity, a fixed ingredient of a material, and its thermal conductivity is independent of thickness or area. |