What are the hazards of Galvanic effect in PCB immersion silver process?Tuesday,Mar 12,2019

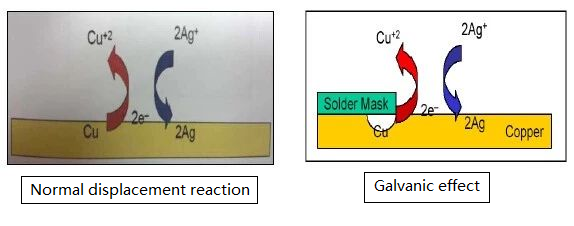

Many customers required us to do immersion silver treatment for their board, immersion silver have a very good flatness, almost the same flatness level with immersion gold, while much cheaper than immersion gold, we have shared an article about the advantage and disadvantage between different surface treatment before. But there has a big quality risk for immersion silver board after our customer received,they are very easily to occur Galvanic effect,today we write an article about Galvanic effect.What is Galvanic effectThe Galvanic effect is also called galvanic corrosion. That is, two connected metals that have different activities are in contact with the electrolyte then occur the galvanic reaction, the more active metal atoms lose electrons and are oxidized (corroded). The essence is that the active metal is oxidized.The principle of Galvanic effect for immersion silver boardNormally, displacement reaction will happened between silver and copper, the low potential elements are oxidized by high-potential elements (electrons lost), while the high potential elements are electron-reduced by getting electrons. In the sinking silver cylinder, Ag ions are electron-reduced in this reaction (2Ag+ + 2e → 2Ag), and copper is oxidized to lose electrons (Cu-→Cu2++2e-). Thus, the oxidation of copper and the reduction of silver ions proceed simultaneously to form a uniform silver plating layer, as shown in the above reaction formula and Figure1 below.

Figure1 Figure2  However, if there is a "crack" between the solder mask and the copper, the supply of silver ions in the crack is limited, but the copper under the solder mask can be corroded into Cu ions, which will provide electrons for Ag+ on the copper pad outside the crack(as shown in Figure 2 above). Since the amount of electrons required is proportional to the amount of reduced Ag ions, the intensity of the Galvanic effect increases with the exposed copper pad surface area and the thickness of the silver layer.

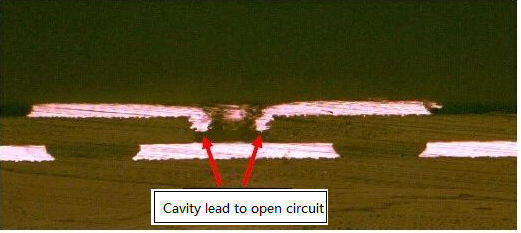

The main defect of immersion silver board caused by Galvanic effectThe main defect caused by Galvanic effect is open circuit as the insufficient copper thickness, the mainly Galvanic effect have these two types:

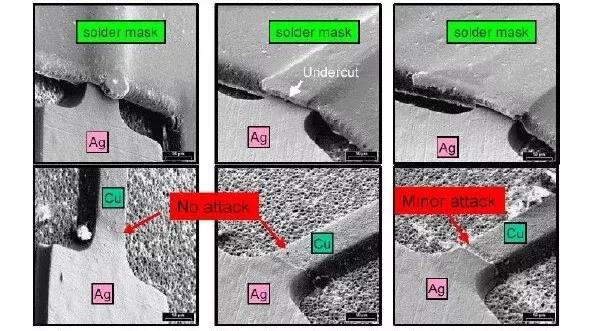

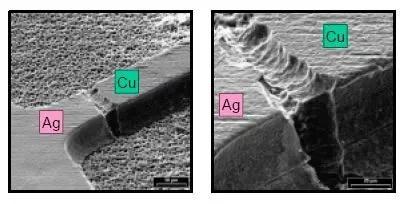

1,Open circuit at the joint of the pad and track covered by the solder mask.In the process of immersion silver, the copper at the undercut place of solder mask be corroded, see Fig. In the process of immersion silver, as the gap between the solder mask and CU is very small, limit the Ag ion supplying, but the Cu can corroded into CU ion, then the copper surface occur immersion reaction outside the gap. Because ion conversion is the motive force of the immersion silver reaction, the degree of attack on the copper surface under the crack is directly related to the thickness of the immersion silver. Uneven electroplated copper layer (thick copper at the hole), there is a noticeable deep scratch on the copper under the solder mask.

Cu corroded at the undercut of solder mask

A thick silver surface produces a moderate galvanic effect

2,The blind hole appeared a cavity after silver immersion, which led to the opening Is there any method to avoid or reduce the Galvanic effect? Yes,the below three ways are our PE summarized:

1,Improve uniformity of the plating copper in the hole wall, and increase hole wall copper thickness. 2,Under the premise of ensuring the customer's silver quality, minimize the micro-etching time and silver immersion time. 3,Install ultrasonic or spout in pre-treatment and silver immersion bath. |